The lathe machine is one of the most frequently used machines. This is not surprising as the machine can do a lot of things with precision. Want to know more about the machine? Read on, then. Here we explain what the machine is, its parts, and its functions.

Daftar Isi

Definition

Before we proceed further, let’s start with the definition first. A lathe is a machining tool used for shaping a workpiece, most of which being wood and metal. How the machine work is simple. It holds a workpiece and rotates it around a stationary tool. By doing so, the unwanted parts of the workpiece are removed.

The lathe is also known as the mother of machines, as it is used to create other machines. There are many types of lathe machines, each of them is specialized to use for different techniques and materials. A lathe consists of many parts, which we will explain in the later section.

Functions

In terms of functions, the lathe is very versatile. It can perform all basic operations such as cutting, turning, drilling, and tapping, among others. It can be used to make parts for other machines and make specialty items like musical instruments and bowls. Lathes are widely used for this reason.

Lathes machines have 4 defining features, they

- Are accurate.

- Have high productivity.

- Have a low production cost.

Can process a wide range of materials, from wood, iron, chrome to manganese.

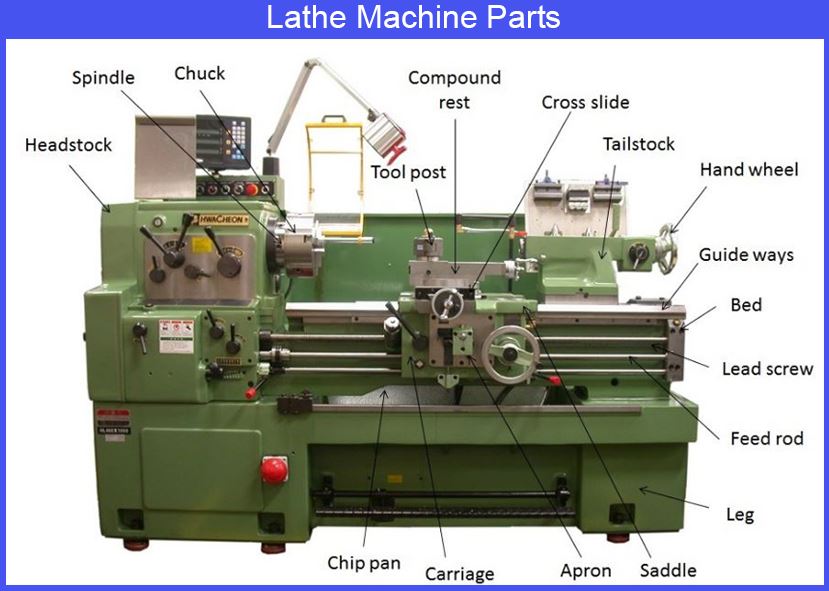

Lathe Machine Parts

A lathe consists of many parts. These parts are:

- Bed

- Headstock

- Tailstock

- Carriage

- Saddle

- Cross-slide

- Compound Rest

- Tool Post

- Apron

- Chuck

- Feel Rod

- Lead Screw

- Spindle

- Leg

We explain each part and its functions below.

1. Bed

This is the base of a lathe. The bed is where the headstock, tailstock, and carriage are mounted. The bed is usually made from cast iron, although there are some others made from nickel cast iron alloy.

It consists of two heavy metal slides. These slides run lengthways, with ways formed upon them. The bed is used to absorb vibration, prevent deflection caused by cutting forces, and support other components of the machine.

2. Headstock

This is the house of the electrical and driving mechanism of the machine. It is located above the bed, on the left side. The main function of this part is to transmit power to other parts of the lathe machine. Headstock supports and aligns the main spindle in the bearing.

3. Tailstock

This part is located above the bed, on the right side. The functions of a tailstock are

- To support for holding as well as minimizing its sagging.

- To hold the tool for the operation.

- To taper for a long job, which is done by offsetting it.

4. Carriage

Carriage is located above the bed, between the headstock and tailstock. Its main functions are to guide, support, and feed the tool against the workpiece during operation. The carriage has five parts: saddle, cross-slide, compound rest, tool post, and apron.

5. Saddle

The saddle is a casting with an “H” shape. It is mounted on top of the lathe machine ways. The main function of a saddle is to provide support to the compound rest, cross-slide, and tool post.

6. Cross-slide

This part is provided with a male dovetail, with which it is assembled on the saddle’s top and a female dovetail on another side. At its top, it is provided with T-slots, allowing coolant attachment and rear tool post to be fixed. Put it simply, the carriage is the part that provides a cross-movement for the cutting tool.

7. Compound rest

The compound rest is located on the cross-slide’s top. The main function of this part is to support the tool post as well as the cutting tool. The compound rest is essential for boring short tapers, turning angels, and forms on forming tools.

8. Tool post

This part is mounted on the compound rest. The tool post’s main function is to hold various cutting tool holders which placed on a wedge, shaped to fit into the concave-shaped ring. There are three types of tool post: squarehead, quick change, and rick and rocker.

9. Apron

The part that hangs over the bed’s front and fastened to the saddle is called the apron. It consists of clutches and gears, which are used for transmitting motion from the machine’s feed rod to its carriage.

There are two commonly used types of Apron: dog or friction clutches and incorporating drop worm mechanism.

10. Chuck

This is the part of a lathe machine that holds the workpiece, especially one that has a short length, large diameter, or irregular shape which makes it unable to be mounted properly between centers. The chuck can be attached to the machine by screwing on its spindle nose.

There are 4 most commonly used types of chucks:

- Four-jaw or independent chuck

- Three-jaw or universal chuck

- Magnetic chuck

- Collect chuck

11. Feed Rod

This is a power transmission mechanism that is used to create a precise linear movement of the carriage along the machine’s longitudinal axis (from the left to right side and vice versa). Not all lathes use a feed rod for this purpose. Some lathes use lead screws instead.

12. Lead Screw

The lead screw is a necessary part if a threading operation is to be done on the machine. A threading operation requires two things: the linear movement of the tool and the rotational movement of the workpiece, both of which are provided with a lead screw.

13. Spindle

It is a hollow cylindrical shaft. Its function is to transmit power from the machine’s transmission system to the workpiece. Because of its shape, the longer length of a workpiece can pass through and be supported by it. The main spindle is designed in a way that the thrust of a cutting tool doesn’t deflect the spindle.

14. Leg

This is the part that carries the full load of the lathe machine and transfers it to the ground. The legs of a lathe are usually secured to the floor using the foundation bolt.

Closing

Now you know the definition of a lathe machine, its parts, and functions. It is a very essential machine that consists of many parts. The machine can be operated in different ways, for various things, including woodworking and metalworking, among others. We hope our introduction of the machine helps.

Muhammad Reza Furqoni atau biasa disapa Reza adalah founder dan CEO di teknikece.com Sebelum mendirikan teknikece.com, ia dikenal sebagai seorang mahasiswa dan aktif menulis artikel terkait perkembangan dunia teknologi.