There are many kinds of machines in the manufacturing industries. However, only a few can be comparable to the milling machine in terms of functions. The machine can do various kinds of milling operations, including angular milling, thread milling, and gear milling, among others.

In this article, we will give a brief introduction to the machine. First, we will tell you the definition of the machine. Then, we tell you the function. Finally, we tell you the parts of the machine.

Daftar Isi

What Is Milling Machine?

Let’s start with the definition first. What is a milling machine? It is a machine used to remove unwanted materials from a workpiece to get the desired shape. This process is done by feeding the workpiece against a revolving cutter (also known as a milling cutter).

Functions of Milling Machine

Milling is a process where unwanted materials are removed from a workpiece by using rotating cutters. Although the working principle is simple, the machine can be used to perform various milling operations, including angular milling, thread milling, and gear milling, just to name a few.

These are the functions of a milling machine. Usually, these machines produce flat surfaces but they can also produce any shape. That is, provided that the desired shape can be ground on the cutter.

Milling Machine Parts

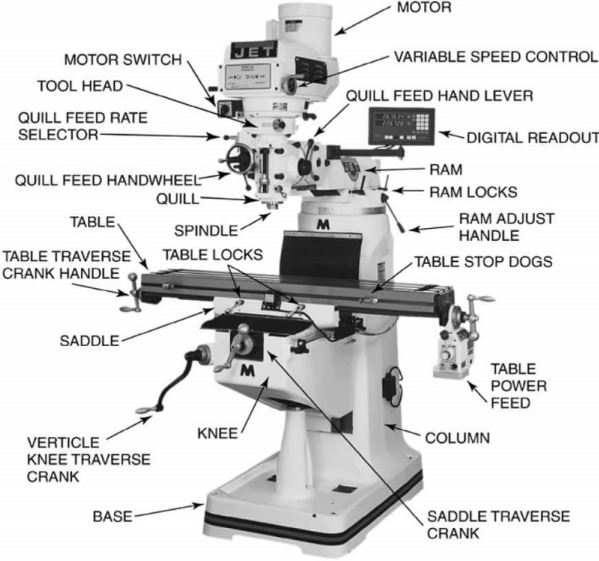

The machine consists of many parts. The main parts of the machine include base and column, knee, saddle and swivel table, power feed mechanism, table, spindle, overarm, arbor, arbor support, and ram. We explain each part and its functions below.

1. Base and column

Base and column are the main castings supporting the rest of the machine as the two are the foundations of the machine. Supporting the other parts is not the only function of the column and base. The two have other functions as well:

- On the base, there is a pump and coolant reservoir. These parts are used during an operation in which coolant is needed.

- On the column, there is a pump and oil reservoir used to lubricate the spindle.

2. Knee

The first moving part of the machine, the knee is the part supporting the saddle and table. The machine’s gearing mechanism is situated in here.

The knee is mounted on the column. The knee is supported by an elevating screw, which can also be used to adjust the vertical positioning of the knee.

3. Saddle

The saddle is located between the table and the knee, working as an intermediary between the two. The saddle can move transversally to the column face. The function of the saddle is to provide movement in a horizontal direction to the workpiece.

In a universal milling machine, a saddle usually has an additional part. Namely, the spin or swivel table. This table can be revolved horizontally.

4. Power Feed Mechanism

Enclosed within the knee, this mechanism is the one that controls the vertical, longitudinal, and transverse feeds.

Other things to know about the power feed mechanism:

- The desired feed rate can be obtained by adjusting the feed selection lever according to the selection plates.

- On some universal machines, the desired feed rate can be obtained by adjusting the speed selection handle. This process is done until the desired rate is shown on the feed dial.

- Most milling machines have a special lever that can be used to temporarily increase the speed of the vertical, longitudinal or transverse feeds when more speed is needed. This lever is known as a rapid traverse lever.

5. Table

On the saddle’s top, there is a rectangular iron casting part. This part is called table. Its main function is to hold the workpiece while a machining operation is done.

The table has a few T-slots. These slots can be used to hold the workpiece and workpiece-hold devices. The operator can operate the table by using their hand (via the hand crank) or by power (via the feed control lever).

6. Spindle

To do the operation, the machine’s cutting tools bust be held and driven. The part of the machine that does this job is known as the spindle. This part is mounted on the machine’s bearings. It is powered by the electric motor via gear trains situated within the column.

The spindle is a moving part of the machine. It is in rotary motion. On its front end, the spindle has a slot in which the cutting tool is fixed.

7. Overarm or Overhanging Arm

At the top of the column there is an over arm (also known as overhanging arm). Made from cast iron, this part overhangs over the surface of the column with its end supporting the arbor.

The main function of the overarm is to fasten the arbor support. The typical overarm consist of one cylindrical bar (in some machines, more) sliding through the holes within the machine’s column.

8. Arbor

The arbor is the mechanical part used as an extension of the spindle in a horizontal machine. The arbor is fitted on the spindle whenever necessary. Its function is to hold and moves the tool in the desired direction.

9. Arbor Support

The arbor does not stand alone. It is supported by the arbor support. This part also has bearing and plays a role in aligning the arbor’s outer end with the machine’s spindle. During cutting operations, the arbor’s outer end might spring. The arbor support prevents this from happening.

In milling machines, there two types of support for arbor. The first type has a small diameter (up to 1-inch diameter) bearing hole and the second one has a larger diameter (up to 23/4 inches) bearing hole.

Other things to know about the arbor support:

- There is an oil reservoir in the arbor support. The oil is used to lubricate the surface of the bearing.

- There are two types of milling machines based on their configuration: horizontal and vertical. The arbor support is used only in the former.

10. Ram

The ram is the overhanging arm that can be found in vertical milling machines. One of its ends is located on the column’s top while the other is attached to the milling head. The operator can move the ram transversally by using a hand lever.

We hope our brief introduction above helps you understand the milling machine better. Although the machine has a simple working simple it can be used for various operations. It is not a surprise the machine is considered one of the most important machines in the manufacturing industries.

Muhammad Reza Furqoni atau biasa disapa Reza adalah founder dan CEO di teknikece.com Sebelum mendirikan teknikece.com, ia dikenal sebagai seorang mahasiswa dan aktif menulis artikel terkait perkembangan dunia teknologi.